Draw Frame

Tasks of Draw frame

Equalizing is always performed by a first process, namely doubling and can optionally also be performed by a second process, namely auto leveling. The draft and the doubling have the same value and lie in the range of 6 to 8.

Parallelizing: To obtain an optional value for strength in the yarn characteristics, the fibers must be arranged parallel in the fiber strand. The draw frame has the tasks of creating this parallel arrangement. It fulfills the task by way of the draft, since every drafting step leads to straightening the fibers.

Blending: In addition to the equalizing effect, doubling also provides a degree of compensation of raw material variation by blending. Their results are exploited in particular way in the production of blended yarns comprising cotton or synthetic blends. At the draw frame metering of the individual components can be carried out very simply be selection of the number of slivers entering the machines.

Dust Removal: Dust is steadily becoming a greater problem both in processing and for the personnel involved. It is therefore important to remove dust to the greatest practical extent at every possible point within the overall process.

Dust removal can only be carried out to a significant when there are high levels of fiber. Since a large function the smallest particles adhere relatively strong to the fibers. High performance draw frame is equipped with appropriate suction removal systems; more than 80% of the incoming dust is extracted.

Draw frame is a machine for combining and drawing slivers of a textile fiber (as of hemp for rope manufacture or cotton for spinning). Drawing is the operation by which slivers are blended, doubled and leveled. In short staple spinning the term is only applied to the process at a draw frame.

In drawing slivers are elongated when passing through a group of pair rollers, each pair is moving faster than previous one.

Actions Involved in Draw Frame

Drafting: It is the process of increasing length per unit weight of sliver. It is mainly due to peripheral speed of the rollers.

Doubling: The process of combing two or more carded sliver into a single form is called doubling. In draw frame m/c generally six slivers are fed to convert into one i.e. six doubling.

Drawing: In the cotton industry the term is applied exclusively to processing on the draw frame, where the operation is one of doubling and drafting. Drawing= Drafting + Doubling.

In drawing slivers are elongated when passing through a group of pair rollers, each pair is moving faster than previous one.

Actions Involved in Draw Frame

Drafting: It is the process of increasing length per unit weight of sliver. It is mainly due to peripheral speed of the rollers.

Doubling: The process of combing two or more carded sliver into a single form is called doubling. In draw frame m/c generally six slivers are fed to convert into one i.e. six doubling.

Drawing: In the cotton industry the term is applied exclusively to processing on the draw frame, where the operation is one of doubling and drafting. Drawing= Drafting + Doubling.

|

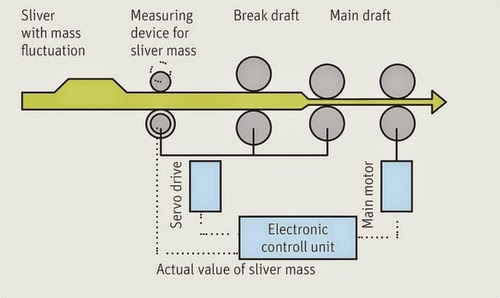

| Diagram of draw frame |

- Equalizing

- Parallelizing

- Blending

- Dust removal

Equalizing is always performed by a first process, namely doubling and can optionally also be performed by a second process, namely auto leveling. The draft and the doubling have the same value and lie in the range of 6 to 8.

Parallelizing: To obtain an optional value for strength in the yarn characteristics, the fibers must be arranged parallel in the fiber strand. The draw frame has the tasks of creating this parallel arrangement. It fulfills the task by way of the draft, since every drafting step leads to straightening the fibers.

Blending: In addition to the equalizing effect, doubling also provides a degree of compensation of raw material variation by blending. Their results are exploited in particular way in the production of blended yarns comprising cotton or synthetic blends. At the draw frame metering of the individual components can be carried out very simply be selection of the number of slivers entering the machines.

Dust Removal: Dust is steadily becoming a greater problem both in processing and for the personnel involved. It is therefore important to remove dust to the greatest practical extent at every possible point within the overall process.

Dust removal can only be carried out to a significant when there are high levels of fiber. Since a large function the smallest particles adhere relatively strong to the fibers. High performance draw frame is equipped with appropriate suction removal systems; more than 80% of the incoming dust is extracted.

This comment has been removed by a blog administrator.

ReplyDelete